| Original research | Peer reviewed |

Cite as: Anderson AV, Fitzgerald C, Baker K, et al. Comparison of shower-in and shower-in plus bench entry protocols for prevention of environmental contamination due to personnel entry in a commercial swine facility. J Swine Health Prod. 2018;26(4):192-199.

Also available as a PDF.

SummaryObjective: To determine if the addition of a bench entry system in a commercial swine facility with a shower lowers the risk of personnel introducing environmental contamination. Materials and methods: Fluorescent powder was used to assess the bench entry system by simulating environmental contamination carried on the footwear of personnel entering a commercial swine farm. On each of ten days, four female employees entered the premises, stepped through the fluorescent powder, performed bench entry procedures, and showered into the farm. For ten additional replicates, the bench was removed and regular farm protocols were followed. The fluorescent powder contamination was evaluated with a grid system at four sampling points including before the bench, after the bench, before the shower, and after the shower. Statistical analysis was conducted to determine if there was a difference in the number of contaminated grid cells found at each sampling between the treatment groups. Results: Fluorescent powder was found after the shower on two study days in which the bench was removed but none when the bench was in place. There was a significant difference in contamination found directly after the bench between days with bench entry and days that the bench was removed, but this was not observed at any of the other sampling points. Implications: A bench entry system may decrease the risk that pathogens reach the clean side of the shower, but improved protocols and additional layers of biosecurity are needed. | ResumenObjetivo: Determinar si la adición de un sistema de banca de entrada con una regadera disminuye el riesgo de que el personal introduzca contaminación medioambiental a una granja porcina comercial. Materiales y métodos: Se utilizó polvo fluorescente para valorar el sistema de banca de entrada, simulando la contaminación medioambiental llevada en el calzado del personal que entra a una granja porcina comercial. En cada uno de los diez días, cuatro empleadas entraron a las instalaciones, pisaron el polvo fluorescente, llevaron a cabo los procedimientos de banca de entrada, y se bañaron para entrar a la granja. En diez repeticiones adicionales, se quitó la banca y se siguieron los protocolos regulares de granja. Se evaluó la contaminación con el polvo fluorescente con un sistema de cuadricula en cuatro puntos de muestreo, incluyendo antes de la banca, después de la banca, antes de la regadera, y después de la regadera. Se realizó un análisis estadístico para determinar si había una diferencia en el número de celdas de la cuadricula contaminadas que se encontraron en cada muestreo entre los grupos de tratamiento. Resultados: Se encontró polvo fluorescente después de la regadera en dos días de estudio en los que se había quitado la banca pero no se encontró contaminación cuando la banca estuvo colocada. Hubo una diferencia significativa en la contaminación que se encontró directamente después de la banca entre los días con banca de entrada y los días en que la banca se quitó, esto no se observó en ninguno de los otros puntos de muestreo. Implicaciones: Un sistema de banca de entrada puede disminuir el riesgo de que los patógenos lleguen al lado limpio de la regadera, pero también son necesarios protocolos mejorados y pasos adicionales de bioseguridad. | ResuméObjectif: Déterminer si l’ajout d’un système d’entrée avec banc dans une entreprise porcine commerciale utilisant la douche à l’entrée diminuait le risque que le personnel introduise une contamination environnementale. Matériels et méthodes: De la poudre fluorescente a été utilisée afin d’évaluer le système d’entrée avec banc en simulant de la contamination environnementale transportée sur les chaussures du personnel entrant sur une ferme porcine commerciale. À chaque jour pendant une période de 10 jours, quatre employées sont entrées sur les lieux, ont marché dans la poudre fluorescente, ont complété la procédure d’entrée avec banc, et pris une douche d’entrée sur la ferme. Pour dix réplications supplémentaires, le banc a été retiré et les protocoles d’entrée réguliers ont été suivis. La contamination par la poudre fluorescente a été évaluée à l’aide d’un système à grille à quatre points d’échantillonnage incluant avant le banc, après le banc, avant la douche, et après la douche. Une analyse statistique a été faite afin de déterminer s’il y avait une différence dans le nombre de cellules de la grille contaminées à chaque point d’échantillonnage entre les deux groupes. Résultats: De la poudre fluorescent a été trouvée après la douche en deux occasions lorsque le banc avait été retiré mais jamais lorsque le banc était en place. Il y avait une différence significative dans la contamination trouvée directement après le banc entre les jours avec entrée avec le banc et les jours lorsque le banc était retiré, mais ceci n’a pas été observé aux autres points d’échantillonnage. Implications: Un système d’entrée avec banc peut diminuer le risque que des agents pathogènes atteignent le côté propre de la douche, mais des protocoles améliorés et des mesures additionnelles de biosécurité sont nécessaires.

|

Keywords: swine, fluorescent powder, bench entry, swine pathogen, biosecurity

Search the AASV web site

for pages with similar keywords.

Received: November 29, 2017

Accepted: February 28, 2018

The United States swine industry accounts for many direct and indirect jobs and is worth approximately $22.5 billion.1 The introduction of new pathogens into swine herds complicates disease management and puts the industry’s profitability and capability to provide jobs at risk. In addition, the United States swine industry continues to struggle with the rapid spread of emerging infectious and transboundary production diseases following their introduction. This is evidenced by the rapid emergence of porcine circovirus type 2 in 2005 and the 2013 introduction of porcine epidemic diarrhea virus which spread to every region of the United States in less than one year. Despite three decades of research, approximately 20% to 40% of breeding herds in the United States undergo a new porcine reproductive and respiratory syndrome outbreak each year,2 costing the industry $664 million dollars in lost productivity annually.3 To prevent ongoing and future economic losses, the industry must identify biosecurity gaps and reduce risk factors to prevent introduction of pathogens, or new isolates of pathogens, into herds.

A risk event occurs when people, animals, or objects that may be contaminated or infected with a pathogen enter a farm. On-farm employee entry is one of the most frequent risk events that occurs on swine farms and can pose a significant threat for pathogen entry when specific biosecurity protocols are absent or poorly implemented.4 Previous research on swine biosecurity protocols for porcine reproductive and respiratory syndrome virus (PRRSV) demonstrated that the virus can be transmitted to PRRSV-naïve pigs by personnel and fomites related to personnel, such as footwear, coveralls, and gloves.5-8 Otake et al5 demonstrated that if no biosecurity measures were taken, personnel that contacted PRRSV-positive pigs could transmit PRRSV to naïve pigs; but if contaminated personnel changed boots, coveralls, and washed hands prior to contacting sentinel animals, PRRSV was not transmitted. Another source of swine pathogen-contaminated material is personnel footwear. Dee et al7 demonstrated that clean boots could be contaminated with PRRSV by contacting the same surface where boots carrying PRRSV contaminated material were placed. Therefore, employees could be carrying the virus on their footwear without ever contacting an infected herd themselves. In response, many breeding herds in the United States implemented shower-in-shower-out procedures. If properly constructed, the shower acts as a line of separation, since the “dirty” side is found before the shower and the “clean” side is found after the shower. All outside clothing and items remain on the dirty side and personnel are required to take a complete shower before stepping into the clean side. Farm dedicated boots and coveralls are provided inside the farm to decrease the risk of swine pathogen entry into farms. However, there is a potential risk of tracking PRRSV or other swine pathogens through the shower room and into the swine facility on farms where personnel take their footwear off in an ante-room and proceed to walk across that same surface in their stocking or bare feet to the showers.

The bench entry system is an additional layer of biosecurity to lower the risk of pathogen transmission from contaminated footwear and ante-rooms. However, no research has been done to date to evaluate if the addition of a bench entry system to commercial swine facilities with a shower is effective at reducing the level of environmental contamination transferred to the clean side of the farm. In human medicine, fluorescing materials have been used to measure and compare environmental contamination with alternative protocols for removal of personal protective equipment.9,10 The use of fluorescing materials may be useful for evaluating the efficacy of bio-exclusion practices to reduce the introduction of environmental contamination into swine farms. The objective of this study was to determine if the addition of a bench entry system at a commercial swine facility with a shower lowers the risk of personnel introducing environmental contamination, as simulated by use of a fluorescent powder.

Materials and methods

Facility and study area

The study was conducted at a Midwest commercial sow farm with 4,000 breeding females. The experimental protocol was approved by the Iowa State University Institutional Review Board and Use Committee (IRB ID: 16-231) prior to initiation of any experimental activity. Personnel were required to shower into and out of the facilities each day, but a bench entry system was not used. The layout of the facility and study area is shown in Figure 1. The showers were located so that personnel were required to pass through them to enter the facilities. The area prior to the showers was considered dirty and the area after the showers was considered clean. The first part of the dirty side was comprised of a doorway through which personnel entered from the outside. The employees would first walk down the hall and hand their lunches and personal items through the office window and then sit down to remove their shoes. The shoes were placed on a shoe rack next to the office window. Directly ahead of the outside door was another door, which lead to the shower hall. After the employees removed their shoes, they walked down the shower hall and entered their respective shower. Normal shower protocols for this farm included removing their clothes, placing all personal items inside a locker, and taking a thorough shower. Employees would then dry off and dress in clothing and boots provided on the clean side of the shower.

Figure 1: Diagram depicting the floor plan of the entry hall, shower hall, and shower rooms. Shower 6 was used to conduct the study. The location of the bench for the Bench treatment days and placement of the fluorescent powder (Glo Germ) are indicated. The location of each sampling point is designated with the letters A, B, C and D.

Study design

A control group (NoBench) and a treatment group (Bench) were evaluated in this study. The NoBench group was the farm’s existing employee entry protocol as previously described. The Bench group included the addition of a bench entry procedure, used by employees for removal of their shoes, to the existing entry protocol. The design of this study was a randomized block design blocked by day of the week, Monday through Friday. Blocking by day was done to control for potential differences in compliance depending on the day of the week. Eight female employees participated in at least one replicate during the study. A single gender was enrolled in the study to avoid the potentially confounding effect of gender related to attention to detail and personal hygiene. On each day of the study, four employees would enter the farm through the study shower, shower 6, and other employees entered through one of the other five showers. The same four employees participated in the study whenever possible, however the other employees participated when scheduling conflicts resulted in the absence of one of the original employees. The experimental unit, therefore, was four employees entering the farm on a single day. The experimental units were blocked by day of week and then randomly assigned within each day of week to one of the two treatment groups (Table 1) using the RAND function in Microsoft Excel (version 2010; Microsoft Corporation, Redmond, Washington). The study was completed over twenty week days (4 weeks). Ten replicates of each treatment group were performed over the twenty study days.

Table 1: Randomly assigned treatments performed during a study comparing the efficacy of two protocols for entry onto a commercial sow farm

| Study day | Date | Treatment* |

|---|---|---|

| Week 1 | ||

| Wednesday | 6/8/2016 | Bench |

| Thursday | 6/9/2016 | NoBench |

| Friday | 6/10/2016 | Bench |

| Monday | 6/13/2016 | Bench |

| Tuesday | 6/14/2016 | Bench |

| Week 2 | ||

| Wednesday | 6/15/2016 | NoBench |

| Thursday | 6/16/2016 | Bench |

| Friday | 6/17/2016 | NoBench |

| Monday | 6/20/2016 | NoBench |

| Tuesday | 6/21/2016 | NoBench |

| Week 3 | ||

| Wednesday | 6/22/2016 | NoBench |

| Thursday | 6/23/2016 | Bench |

| Friday | 6/24/2016 | NoBench |

| Monday | 6/27/2016 | NoBench |

| Tuesday | 6/28/2016 | Bench |

| Week 4 | ||

| Wednesday | 6/29/2016 | Bench |

| Thursday | 6/30/2016 | NoBench |

| Friday | 7/1/2016 | Bench |

| Monday | 7/11/2016 | Bench |

| Tuesday | 7/12/2016 | NoBench |

* The NoBench treatment group was the farm’s existing employee entry protocol, which included shower-in-shower-out procedure. The Bench treatment group included the addition of a bench entry procedure, used by employees for removal of their shoes, to the existing entry protocol.

Study materials

Fluorescent powder. The fluorescent powder (Glo Germ, Glo Germ Company, Moab, Utah) used to simulate the spread of environmental contamination throughout a farm contained particles that were approximately 5 microns or less in size, which is similar to the particle size of many bacteria. It appears white under natural lighting and fluoresces when exposed to ultraviolet (UV) light (Lights of America, Walnut, California).

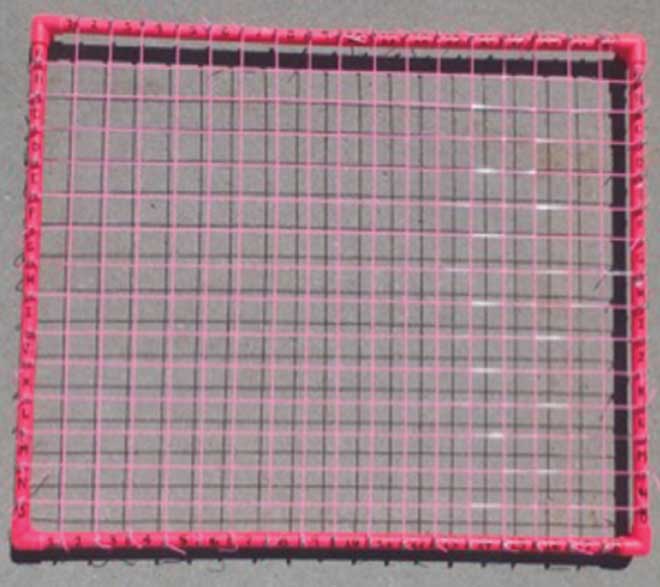

Bench. The bench was constructed from pine wood and was painted with an oil-based primer (KILZ, Santa Ana, California) and a gloss oil-based porch and floor paint (Valspar paint, Salem, New Hampshire) to ensure that the fluorescent powder could be completely removed after each study day. The bench was 96.5 cm in length, 27.9 cm in width, and 50.8 cm in height. All sides of the bench reached the ground and were solid except for hand holes on each of the four sides that were used to remove the bench during the NoBench study days (Figure 2).

Figure 2: Bench used for the Bench treatment days during the study. The bench was 96.5 cm in length, 27.9 cm in width, and 50.8 cm in height. On treatment days, the bench was placed in the hallway just before the shower entry.

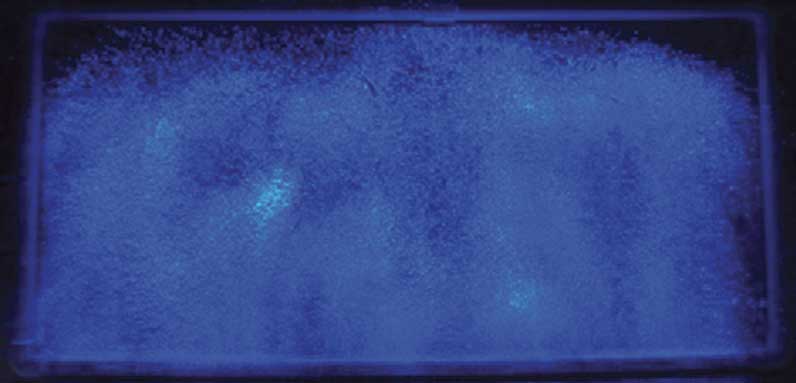

Contamination measurement grids. To evaluate the level of environmental contamination, 90 × 75 cm2 grids were constructed and subdivided into 270 cells that measured 5 × 5 cm2 (Figure 3). They were constructed with PVC pipes (Silver-Line Plastics; Lawton, Oklahoma), 0.48 × 5.08 cm2 metal eyelets, and flat plastic string (Rexlace, Pepperell, Massachusetts). The grids were coated with a pink fluorescent paint (Krylon, Cleveland, Ohio) that showed up under UV light but was a different color than the fluorescent powder. One grid each was used for evaluating the clean and dirty sides of the shower and each grid remained on its respective side for the duration of the study.

Figure 3: The grid that was constructed and used to quantify the amount of fluorescent powder transferred to each of the four sampling locations: 1) hall before bench, 2) hall after bench, 3) dirty side of shower room, and 4) clean side of shower room.

Study procedures

Prior to the start of the trial, study investigators inspected the facilities and prepared for the first study day. The entire area in which the study took place was thoroughly cleaned. The locations where the bench, shoe rack, fluorescent powder, and measurement grids would be placed were marked. An in-person training session lasting 30 minutes was conducted by the study investigators to teach the employees involved in the study how to use the bench and other study procedures. A poster, with instructions in English and Spanish on how to use the bench, was hung above the bench location for the duration of the study. Employees involved in the study were blinded to the purpose of the study and told that the powder was a novel disinfectant.

On each study day, two study investigators arrived at the site prior to the farm personnel. One investigator would shower in to the clean side of the farm using shower 5 and cross over to shower 6 to inspect for any residual fluorescent powder using a UV light. If any residual powder remained from the previous replicate, the researcher would clean the area using soap (Dawn Ultra, The Procter & Gamble Company, Cincinnati, Ohio), a sponge (Lysol, Reckitt Benckiser LLC, Parsippany, New Jersey), water taken from the clean side of the shower, and a clean towel. After cleaning, the researcher would re-inspect the area for any residual fluorescent powder. If any remained, the researcher would repeat the cleaning and inspecting process until no residual powder could be detected. The investigator would then shower out to the dirty side using shower 5 and prepare for the entry of employees. Simultaneously, the second study investigator would inspect the hall leading to the showers, the dirty side of the shower, and the surrounding area for residual fluorescent powder. If any fluorescent powder was detected using the UV light, the area was cleaned using water taken from the dirty side of the shower and the same procedure previously described.

On study days, 4 g of fluorescent powder, a simulated source of contamination, was spread uniformly on the floor of the hall approximately 118 cm prior to the entry of shower 6 (Figure 1). The concrete floor was covered with a non-porous coating, which allowed the researchers to remove all the fluorescent powder after each replicate. To ensure that the fluorescent powder was spread in the same location each day, a PVC pipe (Silver-Line Plastics; Lawton, Oklahoma) outline was built. The outline was 45 × 104.5 cm2 and fit tightly between the two walls on either side of the hall leading to the showers (Figure 4). Following setup, four female personnel entered the facility individually and walked down the hall to the showers in their outdoor footwear, instead of removing them in the entry hallway.

Figure 4: Fluorescent powder, as seen under an ultraviolet light, was spread within a PVC pipe frame to ensure application in the same location each day.

On NoBench study days, each employee had to step through the fluorescent powder to get to the shoe rack on which they would place their shoes. Once the employees had removed their shoes and placed them on the shoe rack (Figure 1), they would walk through the doorway into shower 6. Each employee would follow the swine facility’s normal entry protocol following entrance into the shower.

On Bench treatment days, the researchers would set up the bench for employees to use in the designated location (Figure 1). When the employees arrived, they walked down the hall in their outside shoes and stepped through the fluorescent powder that had been sprinkled on the floor. The employees sat down on the bench with both their feet on the dirty side of the bench. They would remove their left shoe, place it on the shoe rack, and swing their left leg over to the clean side of the bench without touching their foot on the floor of the dirty side. Next, they would repeat this procedure with their right shoe. Employees were closely monitored to ensure that they did not touch their socked or bare feet on the floor of the dirty side of the bench. Finally, the employees would enter shower room 6 and follow the swine facility’s normal shower protocol. Employees were monitored as they entered the facility each study day to ensure that procedures covered in the training were followed. If a deviation from the training occurred, the data from that replicate would not be included in the statistical analysis and that study day would be repeated on the same day of a different week.

After the four farm employees entered the swine facility, the level of contamination was measured at the four sampling points: A) hall before bench, B) hall after bench, C) dirty side of shower room, and D) clean side of shower room (Figure 1). Each of the four sampling points was marked inconspicuously on the floor to ensure that the placement of the grid and location measured would not vary between study days. The lights were turned off and the UV light was used to illuminate the grid and any fluorescent powder within the grid. The primary investigator would observe the grid and call out the grid coordinates of the cells that had visible contamination with fluorescent powder. The secondary investigator would mark down the results on a pre-printed illustration of the grid for each sampling point. If there was any powder inside the cell of the grid, it was counted as contaminated. This was repeated for each sampling point. After taking measurements on the dirty side of the shower (sampling points A, B, and C), the primary investigator would shower through to the clean side of the farm using shower 5 and take measurements on the clean side of shower number 6 (sampling point D). The primary investigator identified contaminated cells at all sampling points (A, B, C, and D) on every day of the study to minimize variability.

After all measurements of contamination were completed, the investigators used dishwashing soap, a sponge, and water to clean the entire study area. After cleaning, the areas were inspected with the UV light to ensure no residual fluorescent powder remained. If there was any residual fluorescent powder, the area was re-cleaned and inspected until none remained.

Statistical analysis

All data was analyzed using SAS 9.4 (SAS Institute, Cary, North Carolina). Differences in contamination at each of the sampling points between the Bench and NoBench groups were compared using a two-tailed Wilcoxon rank sum test when normality conditions were not satisfied. All reported differences were considered significant at P < .05 and there was no adjustment for repeated measures.

Results

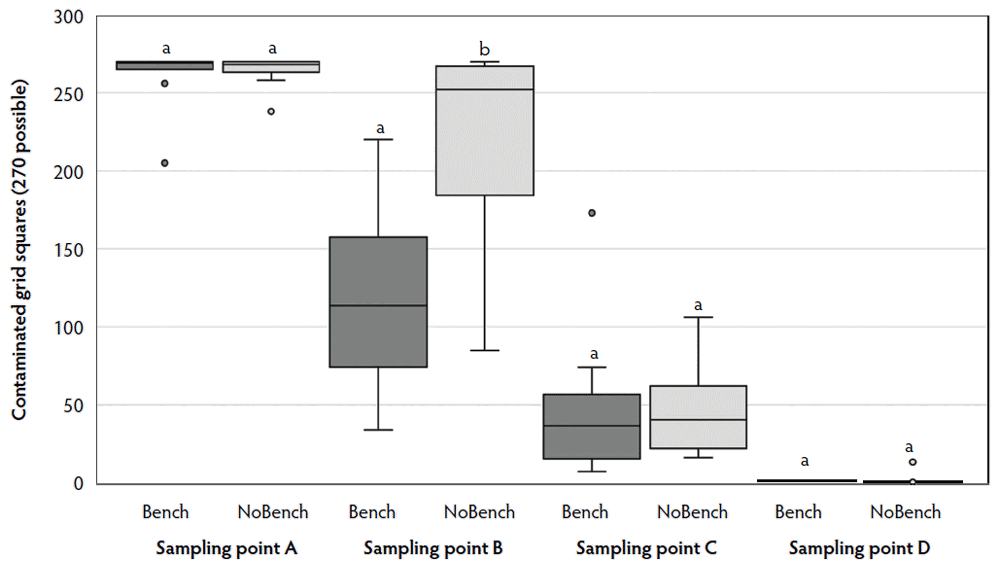

The number of contaminated cells was significantly (P < .05) lower for the Bench treatment group at sampling point B (directly after bench) but not at any of the other sampling points (Figure 5). The mean number of contaminated cells declined as the employees progressed from the area closest to the contamination (sampling point A) to the clean side of the shower (sampling point D) for both treatment groups. Fluorescent powder was not found on the clean side of the shower on any Bench treatment days. However, it was found on the clean side of the shower on two NoBench days; 14 contaminated cells on a Wednesday and one on a Friday. No replicates had to be discarded and repeated due to deviations from procedures covered in the training.

Figure 5: Distribution of the number of contaminated grid cells at sampling points A, B, C, and D for Bench and NoBench groups. The whiskers represent the minimum and maximum values recorded for each point excluding outliers (indicated by dots), and the upper and lower boxes represent the means of the 75th percentile and 25th percentile, respectively. Differing superscripts (a,b) within a sampling point indicate significant differences for Bench and NoBench groups (P < .05; two-tailed Wilcoxon rank sum test).

Discussion

The bench entry inconsistently reduced the level of contamination under experimental conditions, highlighting the need to focus on execution of entry and shower procedures. Before the study, employees were trained on proper use of the bench entry system and were monitored throughout the study for any deviations from procedures covered in the training. Study investigators were able to anticipate when a deviation might occur and were able to warn the employee. Consequently, no deviations occurred that would have necessitated a study day be repeated. Under field conditions where employees are not monitored, the level of contamination measured may be substantially different from this study. How employees should remove their shoes as they sat on the bench was not covered in the training and it was noted that they frequently touched the bottom of their shoes, transferring the contaminant to their hands and to anything their hands touched subsequently. It was commonly seen that the bench, walls, door handles, light switches, lockers, and shower curtains would have contaminant on them after the employees entered the farm through the Bench entry system, as well as during the NoBench entry system. Personnel clothing also needs to be considered. The investigators observed that pants worn by an employee during one study day were long enough to drag on the ground, which led to high levels of contamination on that study day. This was a Bench replicate, and although the employee used the correct procedure to remove her shoes and cross the bench, an unusual amount of fluorescent powder was transferred to sampling point C where 173 of the 270 grid cells contained fluorescent powder. The other nine Bench replicates had an average of 34 cells with contamination. These results emphasize the need to incorporate clothing and footwear choices, as well as footwear removal procedures, into personnel entry protocols to increase efficacy of the bench entry and shower systems.

A novel approach was used in this study to evaluate bio-exclusion practices designed to reduce the entry of pathogens into swine herds. Consequently, the sample size and study length were selected arbitrarily. The grid used to quantify the contamination was also novel. While the grid proved to be useful for quantifying contamination, some shortcomings were observed. The most notable was that a 5 × 5 cm2 square was counted as contaminated whether contamination covered the entire area in the square or there was only a small speck. A method to measure the exact area of contamination would provide a more precise way of measuring contamination with a higher level of resolution. Additionally, in order to construct a bench that could be removed during NoBench days, the bench did not span the entire width of the hall and left a small gap on one side between the wall and the bench. Moreover, the height of the shoe rack placed beside the bench was greater than the height of the bench itself. The gap beside the bench, the height of the shoe rack, and the ability of the fluorescent powder to easily aerosolize may have contributed to some of the contamination on the clean side of the bench (sampling points B and C).

The results of this study also highlight the importance of layering biosecurity practices. Layering is accomplished by implementing multiple biosecurity procedures, such as the shower and bench, to increase the number of failures that must occur for a pathogen to enter a herd. On two NoBench days, fluorescent powder was found on the clean side of the shower but was never found on Bench treatment days. While the differences in measured contamination on the clean side of the shower between the Bench and NoBench groups were not statistically significant, the results suggest that individual practices that are partially effective in isolation may reduce the risk of pathogen introduction when layered with other practices.

Implications

- This study provides a novel approach to evaluate the efficacy of bio-exclusion procedures on swine farms using a fluorescent powder to simulate environmental contamination.

- Provided the protocol is strictly followed, a bench entry system adds an additional layer of biosecurity and may decrease the risk of pathogens being spread by contaminated footwear to the clean side of the farm.

• Entry protocols should be improved to include detail about appropriate clothing and footwear choices and footwear removal techniques.

Acknowledgements

This study was funded by the American Association of Swine Veterinarians Foundation. The authors thank Iowa Select Farms, the farm employees, and the farm manager for providing access to the facility where the project was conducted.

Conflict of interest

None reported.

Disclaimer

Scientific manuscripts published in the Journal of Swine Health and Production are peer reviewed. However, information on medications, feed, and management techniques may be specific to the research or commercial situation presented in the manuscript. It is the responsibility of the reader to use information responsibly and in accordance with the rules and regulations governing research or the practice of veterinary medicine in their country or region.

References

1. United States Department of Agriculture. 2012 census of agriculture. http://www.agcensus.usda.gov/Publications/2012/Online_Resources/Highlights/Hog_and_Pig_Farming/. Published June 2014. Accessed December 20, 2016.

2. Tousignant SJP, Perez AM, Lowe JF, Yeske PE, Morrison RB. Temporal and spatial dynamics of porcine reproductive and respiratory syndrome virus infection in the United States. Am J Vet Res. 2015;76(1):70-76.

3. Holtkamp DJ, Kliebenstein JB, Neumann EJ, Zimmerman JJ, Rotto HF, Yoder TK, Wang C, Yeske PE, Mowrer CL, Haley CA. Assessment of the economic impact of porcine reproductive and respiratory syndrome virus on United States pork producers. J Swine Health Prod. 2013;21(2):72-84.

*4. Canon A, Gerardy K, Mowrer C, Karriker L, Holtkamp D. PRRS, SVA, Emerging and Transboundary Diseases – Systematically Investigating Swine Disease Outbreaks with the Outbreak Investigation Program. In: Proc from the James D. McKean Swine Dis Conf. Ames, IA. 2015;94-97.

5. Otake S, Dee SA, Rossow KD, Deen J, Joo HS, Molitor TW, Pijoan C. Transmission of porcine reproductive and respiratory syndrome virus by fomites (boots and coveralls). J Swine Health Prod. 2002;10(2):59-65.

6. Dee SA, Deen J, Rossow KD, Wiese C, Otake S, Joo HS, Pijoan C. Mechanical transmission of porcine reproductive and respiratory syndrome virus throughout a coordinated sequence of events during cold weather. Can J Vet Res. 2002;66(4):232-239.

7. Dee S, Deen J, Pijoan C. Evaluation of 4 intervention strategies to prevent the mechanical transmission of porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2004;68(1):19-26.

8. Pitkin A, Deen J, Dee S. Further assessment of fomites and personnel as vehicles for the mechanical transport and transmission of porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2009;73(4):298-302.

*9. Oldham J. Epidemic Diarrhea – How it all began. Pig Farming. 1972; Oct Suppl:72-73.

10. Casanova L, Alfano-Sobsey E, Rutala WA, Weber DJ, Sobsey M. Virus transfer from personal protective equipment to healthcare employees’ skin and clothing. Emerg Infect Dis. 2008;14(8):1291-1293.

* Non-refereed references.