Farm biosecurity is an integral aspect of maintaining herd health. Movement and isolation of animals, human traffic, and pests can all pose a risk of a biosecurity infraction. Viruses, such as porcine reproductive and respiratory syndrome virus, can be transferred from boots to vehicles and to other farms.1,2 Under simulated conditions, lax biosecurity measures have been shown to increase the spread of porcine epidemic diarrhea viruses compared to rigorous biosecurity measures, such as showers and changing clothes.3

Upholding the health of the farm is reliant on the ability of workers to continuously implement existing biosecurity protocols. Lapses in biosecurity compliance, especially in times of perceived low infection risk or during worker shortages, can cause biosecurity breaches. During simulated games, players were more likely to break biosecurity to earn a higher payout when they were more certain animals would not become infected.4,5 Frequent biosecurity breaches were observed when 8 poultry farms were surveyed using hidden cameras. During the surveillance time, 44 types of biosecurity errors were made, with 2 to 7 errors occurring per day per farm.6 Biosecurity breaches tend to happen when personnel rush through work and are often done unintentionally. It is difficult for employers to visually demonstrate a biosecurity breach when teaching new employees or visitors without endangering animal health.

Glo Germ Company manufactures fluorescent gels and powders which can simulate germs or other contaminants under ultraviolet (UV)-A light. Glo Germ has been used in research settings to compare handwashing techniques and as a demonstration for aseptic technique in hospitals.7,8 Spreading Glo Germ throughout a deli revealed areas of cross-contamination between the original equipment and the doors, meat products, and prep equipment.9 Similarly, Glo Germ has been used to evaluate biosecurity exit protocols when applied to lab coats and gowns and has been used on farms to demonstrate lines of separation.10-12 The different applications have all demonstrated Glo Germ’s ability to be used as a teaching aid to improve biosecurity aptitude of individuals and the opportunity for continued use in swine facilities to teach biosecurity principles. Therefore, the objective of this study was to use Glo Germ within a swine operation to demonstrate the efficacy of common biosecurity protocols and be used as a visible teaching aid for future students and farm personnel.

Materials and methods

The Kansas State University Institutional Review Board approved the protocol used in this experiment. The study was conducted concurrently with the spring 2021 swine undergraduate research class (UGR). Prior to the start of the trial, all undergraduate students were taught the biosecurity protocols of the farm. Students were not made aware how the biosecurity protocols were being evaluated or why there was powder in key areas throughout the farm.

Glo Germ coverage

Four different locations at the Kansas State University Swine Teaching and Research Center were photographed weekly for 7 weeks to assess the efficacy of the biosecurity measures to prevent movement of the Glo Germ powder (Glo Germ Company). All pictures were taken on a standard iPhone mounted on a polyvinyl chloride (PVC) frame with attached blacklights (Figure 1) which could be transported to each location. The PVC frame measured 2 × 2 × 2 ft and was wrapped in a large black trash bag to block the surrounding light. Two UV light-emitting diode flashlights (Rayovac; Energizer Brands, LLC) were mounted equal distance apart on the center beam of the frame. Markers were placed on the flooring to align the PVC frame to ensure consistency when photographing the locations.

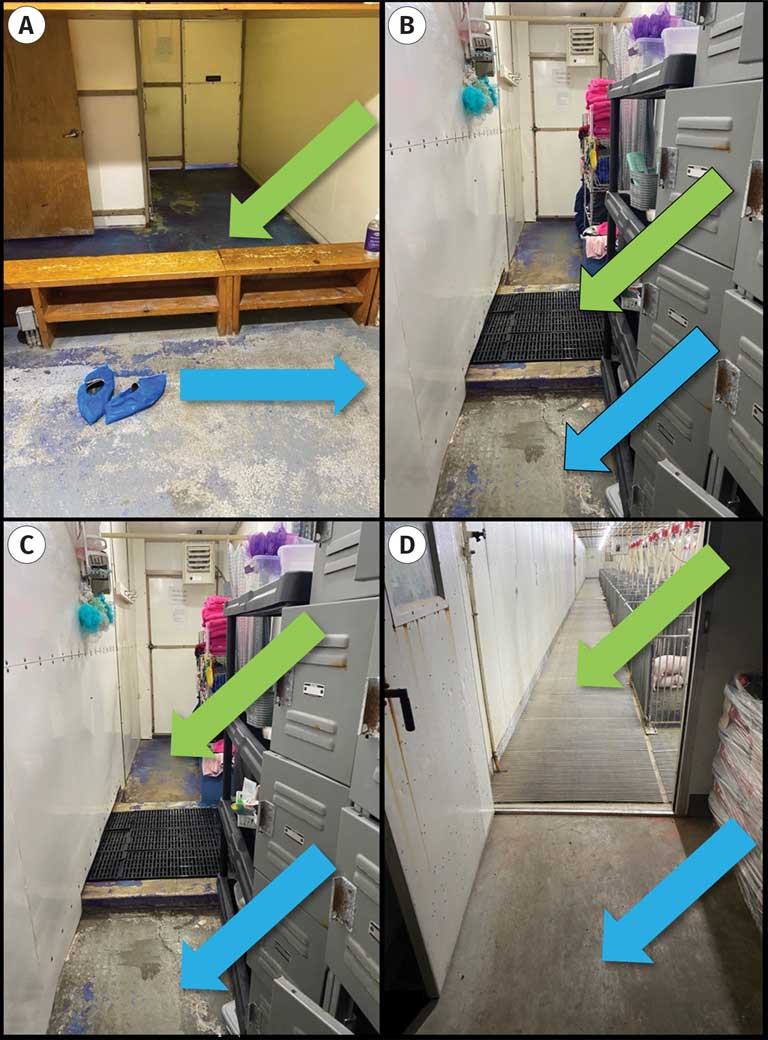

The biosecurity measures tested were 1) entry benches, 2) showering into a farm, and 3) no biosecurity measures (control). The locations used to test these measures were 1) the clean side of the entry bench into the farm, 2) the flooring within the shower, 3) the clean side of the locker room after completing the required shower, and 4) within the barn (Figure 2). Glo Germ was spread in areas preceding the clean areas such as outside the entry door, the dirty side of the locker room, and the feed room used in the barn. The clean areas were cleared of any remaining Glo Germ from the prior week on the evening before the UGR’s weekly weigh day, and photographs were taken of these areas to serve as “before” pictures. Floors in the locker room and entry area were cleaned with a Swiffer WetJet (Procter & Gamble Company), while the floors in the barn were cleared with paper towels and a spray disinfectant. All cleaned areas were exposed to UV lights to ensure no Glo Germ remained in the testing area; if any remained, cleaning was repeated. Following student entry onto the farm, “after” photographs were taken of the same areas. These before and after pictures were blindly evaluated by 47 panelists to determine the quantity of Glo Germ coverage visible within each photograph on a scale from 0% to 100% coverage; each picture was assessed once per panelist. Panelists were provided photographs with examples of 0% and 70% Glo Germ coverage within each location to use as a reference. The assessed quantity of visible Glo Germ was then averaged across all panelists so that each photograph was represented by a single value. Before and after Glo Germ means were then aligned and the difference between the means for each location within a day was calculated. These mean differences represent the increased quantity of Glo Germ visible between the before and after pictures.

Statistical analysis

Data were analyzed using a linear model fit using the GLIMMIX procedure of SAS v 9.4 (SAS Institute Inc). Location on a given day was the experimental unit, and data were analyzed as the mean change in before and after panelist-assigned Glo Germ coverage at each location on each day of evaluation. Location was considered a fixed effect in the statistical model. Least squares means were reported using a Tukey multiple comparison adjustment.

Results

The control location had increased Glo Germ coverage compared to the 3 other locations (P < .001), as would be expected considering no biosecurity measures were in place to prevent movement of Glo Germ onto the surface evaluated. The 3 locations with biosecurity measures in place did not have increased Glo Germ coverage above 1% following movement of students through the 3 locations. The mean difference in Glo Germ coverage of the control location, however, was 19.5% across the 7 weeks (Figure 3). There was no evidence of a difference in Glo Germ coverage between the entry bench, shower floor, or clean side of the shower (P > .05).

Due to the subjective nature of the panelists, there was some variation between the Glo Germ coverage scores. The SEM for the entry bench, shower floor, and clean side of the shower were less than half a percent different from the mean (0.46%, 0.43%, and 0.28%, respectively). Glo Germ coverage for the control location was greater than the other locations with an SEM of 2.97%.

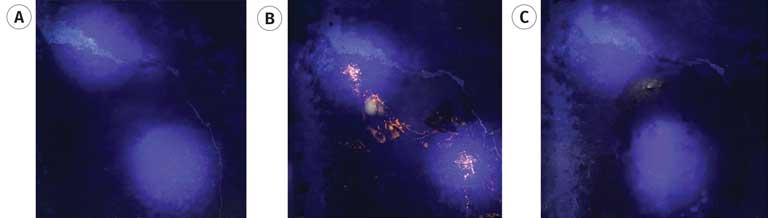

Visual evidence of a biosecurity breach was apparent during week 2 of this experiment. Figure 4A is the floor of the clean side of the locker room prior to any student and personnel movement. Figure 4B is of the same area after a biosecurity breach with increased visible coverage of orange Glo Germ. In contrast, Figure 4C shows the same location from week 3 with little to no visible Glo Germ after all student and personnel successfully showered through and stopped the spread of Glo Germ.

Discussion

Fomites, such as boots and coveralls, have been identified as sources of viral transmission in previous studies.3,13,14 These studies found that a lack of handwashing and not changing clothing and shoes between groups of animals led to infection and cross-contamination of pathogens. However, like most viral work, the research was conducted in a biosecure facility and is hard to replicate on a commercial farm or alongside farm personnel.

Implementing Glo Germ at the farm allowed students and personnel to see the difference biosecurity measures can make in reducing pathogen introduction. In the control location, increased quantities of Glo Germ could be seen without UV light and could be tracked throughout the barn. However, areas where biosecurity measures were followed greatly reduced the quantity of visible Glo Germ and predominantly stopped the spread of Glo Germ altogether. Similarly, Anderson et al11 included an entry bench prior to the showers at a commercial swine farm and saw reduced coverage of Glo Germ beyond the bench and no visible Glo Germ after the bench and shower. Julien and Thomson15 also used Glo Germ as a teaching aid for poultry producers. Producers were impressed that Glo Germ provided a quick visual and efficiently demonstrated the gaps in biosecurity.

One biosecurity breach was observed during our trial. Glo Germ was observed on the clean side of the locker room following the shower. It was most likely due to personnel undressing on the dirty side of the locker room, stepping through the Glo Germ powder, walking across the shower without washing off, and stepping onto the clean side. The reason for this breach is largely unknown but could have been caused by someone rushing into the farm late or assuming they were not at risk for bringing pathogens onto the farm and decided to skip the shower. Time constraints have previously been cited as the reason for a lapse in biosecurity even if the worker was aware of the necessary protocols.16

Biosecurity continues to be a difficult subject for employers to teach and for farm personnel and visitors to continuously uphold. Breaches of varying extremes are common in farms; however, the risk of pathogen introduction remains a constant threat. Demonstrating the potential spread of and contamination by a pathogen will help reiterate the need for biosecurity protocols on farms. Visual aids, such as Glo Germ, are easy and effective ways to exhibit biosecurity compliance and highlight any breaches within a farm.

Acknowledgments

Conflict of interest

None reported

Disclaimer

Scientific manuscripts published in the Journal of Swine Health and Production are peer reviewed. However, information on medications, feed, and management techniques may be specific to the research or commercial situation presented in the manuscript. It is the responsibility of the reader to use information responsibly and in accordance with the rules and regulations governing research or the practice of veterinary medicine in their country or region.

References

1. Dee SA, Deen J, Rossow K, Wiese C, Otake S, Soo Joo H, Pijoan C. Mechanical transmission of porcine reproductive and respiratory syndrome virus throughout a coordinated sequence of events during cold weather. Can J Vet Res. 2002;66:232-239.

2. Dee SA, Deen J, Rossow K, Wiese C, Eliason R, Otake S, Soo Joo H, Pijoan C. Mechanical transmission of porcine reproductive and respiratory syndrome virus throughout a coordinated sequence of events during warm weather. Can J Vet Res. 2003;67:12-19.

3. Kim Y, Yang M, Goyal SM, Cheeran MC-J, Torremorell M. Evaluation of biosecurity measures to prevent indirect transmission of porcine epidemic diarrhea virus. BMC Vet Res. 2017;13:89. https://doi.org/10.1186/s12917-017-1017-4

4. Merrill SC, Moegenburg S, Koliba CJ, Zia A, Trinity L, Clark E, Bucini G, Wiltshire S, Sellnow T, Sellnow D, Smith JM. Willingness to comply with biosecurity in livestock facilities: Evidence from experimental simulations. Front Vet Sci. 2019;6:156. https://doi.org/10.3389/fvets.2019.00156

5. Trinity L, Merrill SC, Clark EM, Koliba CJ, Zia A, Bucini G, Smith JM. Effects of social cues on biosecurity compliance in livestock facilities: Evidence from experimental simulations. Front Vet Sci. 2020;7:130. https://doi.org/10.3389/fvets.2020.00130

6. Racicot M, Venne D, Durivage A, Vaillancourt J-P. Description of 44 biosecurity errors while entering and exiting poultry barns based on video surveillance in Quebec, Canada. Prev Vet Med. 2011;100:193-199. https://doi.org/10.1016/j.prevetmed.2011.04.011

7. Turner JG, Gauthier DK, Roby JR, Larson E, Gauthier JJ. Use of image analysis to measure handwashing effectiveness. Am J Infect Control. 1994;22:218-223. https://doi.org/10.1016/0196-6553(94)90071-X

8. Mittal MK, Morris JB, Kelz RR. Germ simulation: A novel approach for raising medical students awareness toward asepsis. Simul Healthc. 2011;6:65-70. https://doi.org/10.1097/SIH.0b013e318206953a

9. Maitland J, Boyer R, Gallagher D, Duncan S, Bauer N, Kause J, Eifert J. Tracking cross-contamination transfer dynamics at a mock retail deli market using GloGerm. J Food Prot. 2013;76:272-282. https://doi.org/10.4315/0362-028X.JFP-12-271

10. Guo YP, Li Y, Wong PLH. Environment and body contamination: A comparison of two different removal methods in three types of personal protective clothing. Am J Infect Control. 2014;42:e39-e45. https://doi.org/10.1016/j.ajic.2013.12.021

11. Anderson AV, Fitzgerald C, Baker K, Stika R, Linhares D, Holtkamp DJ. Comparison of shower-in and shower-in plus bench entry protocols for prevention of environmental contamination due to personnel entry in a commercial swine facility. J Swine Health Prod. 2018;26:192-199.

12. Ruston CR, Linhares D, Blay E, Nickel M, Skoland K, Kittrell H, Brown J, Karriker L, Breuer M, McKeen L, Holtkamp DJ. Evaluation of a staged loadout procedure for market swine to prevent transfer of pathogen contaminated particles from livestock trailers to the barn. J Swine Health Prod. 2021;29:234-243.

13. Otake S, Dee SA, Rossow KD, Deen J, Soo Joo H, Molitor TW, Pijoan C. Transmission of porcine reproductive and respiratory syndrome virus by fomites (boots and coveralls). J Swine Health Prod. 2002;10:59-65.

14. Pitkin A, Deen J, Dee SA. Further assessment of fomites and personnel as vehicles for the mechanical transport and transmission of porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2009;73:298-302.

15. Julien D, Thomson S. Interactive methods to educate and engage poultry producers on the importance of practicing on-farm biosecurity. J Agric Ext Rural Dev. 2011;3:137-140.

16. Millman C, Christley R, Digby D, Dennis D, O’Brien SJ, Williams N. “Catch 22”: Biosecurity awareness, interpretation and practice amongst poultry catchers. Prev Vet Med. 2017;141:22-32. https://doi.org/10.1016/j.prevetmed.2017.04.002

PDF version

PDF version RIS

citation

RIS

citation