On-farm humane pig handling is important for pig welfare, caretaker safety, and improved product.1 When a pig becomes nonambulatory, the trained caretaker must make an ethical decision if it is in the pig’s best interest to be moved for recovery or to be humanely euthanized. A nonambulatory, noninjured pig that has become fatigued has a high likelihood of recovery and humanely moving them would be ethically correct. However, a pig that has an injury such as a displaced hip or broken leg must be euthanized in place.1 The National Pork Board provides guidance about humane swine handling through the Pork Quality Assurance (PQA) Plus and Transport Quality Assurance (TQA) programs.1,2 Building on these educational programs, the Common Swine Industry Audit (CSIA) is an audit tool designed to meet company and customer needs,3 and includes requirements for humane swine handling. Willful acts of abuse and neglect are strictly prohibited critical elements of CSIA that can result in automatic audit failure and are described as, “[d]ragging of conscious animals by any part of their body except in the rare case where a non-ambulatory animal must be moved for a life-threatening situation. Non-ambulatory pigs may be moved by using a drag mat.”3 Nonambulatory pigs may be moved into hospital pens to facilitate recovery. There is limited evidence in the literature to suggest the impact of different handling tools, including drag mats, on a pig’s response. To provide scientific evidence, initial research used cadavers to identify potentially viable handling tools and to eliminate tools that were impractical or clearly harmful to pigs. In a previous study4 a wean-to-finish mat was eliminated when none of the employees were able to move 3 pig cadavers (68 kg, 118 kg, and 135 kg) from the home pen to the hospital pen. In a second study5 we evaluated a sked, a deer sled, and a modified deer sled with straps using 15 pig cadavers (59-134 kg). The sked and modified deer sled were found to be suitable for moving cadavers; these handling tools were selected for further evaluation with live nonambulatory pigs. In the absence of straps on the deer sled, the cadavers were poorly restrained such that head and legs would catch on penning; this handling tool was not studied further. Consistent with the 3 Rs for ethical animal use in research (reduce, refine, and replace) cadavers were used instead of live pigs (replace) in our initial work evaluating the handling tools, from which modifications were made before use with live pigs. An ice fishing sled has restraints and moves over a variety of terrains and so was considered as a possible option for further testing. Therefore, the objective of this study was to evaluate an HMH sked rescue system, revised deer sled, and ice fishing sled as humane handling tools for moving nonambulatory pigs on a commercial wean-to-finish farm.

Animal care and use

All research was approved by Iowa State University Institutional Animal Care and Use Committee (Approval No. 18-319).

Materials and methods

Handling tools

The 3 handling tools evaluated in this study were selected based on 4 criteria: 1) durability, 2) ability to traverse a variety of surfaces, 3) ability to withstand heavy weights, and 4) presence of restraints.

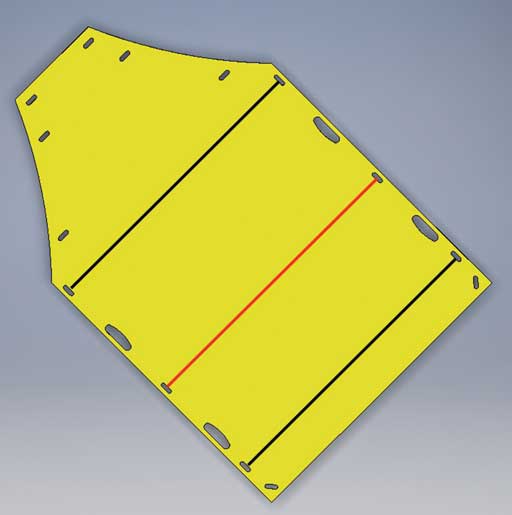

Handling tool 1. An HMH sked rescue system (sk-250; Skedco, Inc) was purchased. The HMH sked rescue system weighed 5 kg, measured 240 cm long × 91 cm wide × 0.3 cm deep and was made of medium-density polyethylene plastic. The HMH sked rescue system was modified to reduce length so transitioning between pens and alleyways was possible. All straps from the HMH sked rescue system were removed except for 3 side-release plastic buckle straps (5.08-cm-wide polypropylene straps). Across the width of the HMH sked rescue system’s foot-end, a 31.1 cm line was drawn and a hacksaw was used to cut across the line. The final sked dimensions were 190 cm long × 91.4 cm wide (Figure 1). The HMH sked rescue system cost $327 with $0 for modifications.

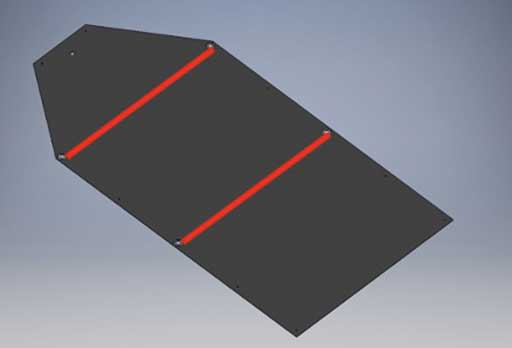

Handling tool 2. A Magnum Deer Sleigh’r Game Sled (Item No. 138755; Sportsman Guide) was purchased. The deer sled weighed 2 kg, measured 180 cm long × 92 cm wide × 0.2 cm deep and was made of slick polymer. Modifications were made to affix new restraints and a polypropylene rope was added to serve as a handle. Two grommets (4 cm) were installed on both sides of the deer sled. One grommet was inserted 50 cm from the top and 2.5 cm from the side. A second grommet was inserted 55 cm below the first grommet and 2.5 cm from the side. The process was repeated on the opposite side of the deer sled. Two side-release plastic buckle restraint straps (6-cm-wide polypropylene straps) were affixed to the grommets. A 3.7-m polypropylene rope was inserted through 3 pieces, 20 cm each, of braided vinyl tubing. The top handle was created with 2 additional handles added underneath (31 cm apart) to provide employees with handle length options when moving pigs. The handle was inserted and knotted on the upper surface of the deer sled. Final revised deer sled dimensions were 180 cm long × 91.8 cm wide (Figure 2). The revised deer sled cost was $30 and an additional $114 for modifications.

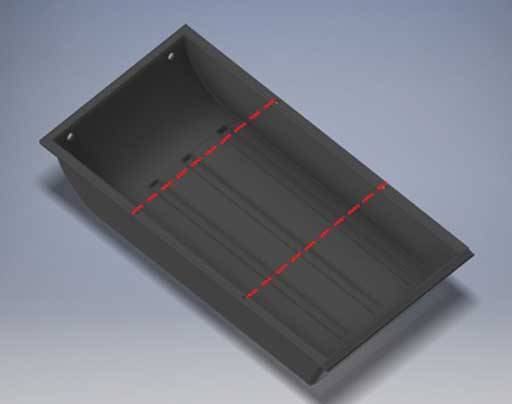

Handling tool 3. An Otter Pro Sled Mini (ice fishing sled; SKU: 200817) was purchased. The ice fishing sled weighed 4 kg, measured 109 cm long × 58 cm wide × 27 cm deep and was made of polyethylene material. Modifications were performed to affix new restraints and a polypropylene rope was added to serve as a handle. Two holes were drilled on both sides of the outer edge. A hole was drilled at 41 and 81 cm from the top of the ice fishing sled. Two side-release plastic buckle restraint straps (5-cm-wide polypropylene straps) were affixed to the holes. Two additional holes were drilled into the front of the ice fishing sled using a 1-cm spade bit to increase the size of the pre-existing holes. A 2.7-m polypropylene rope was inserted through a section of 25-cm braided vinyl tubing. The handle was knotted at the front, upper surface (Figure 3). The ice fishing sled cost $50 with an additional $19 for modifications.

Animals, employees, and facilities

The study was conducted on a commercial grow-finish site in central Iowa. Two production well-being employees were enrolled in the study. The male employee was 60 years of age, 180.3 cm tall, weighed 90.7 kg, and had 20 years of experience. The female employee was 30 years of age, 160.2 cm tall, weighed 63.5 kg, and had 10 years of experience. Eighteen commercial crossbred pigs were selected from the general population by the company veterinarian. Body weights were collected using a weigh scale (Raytec WayPig 300; AGRIsales Inc) and rounded to the nearest whole number. The mean (SD) body weight was 98.4 (25.3) kg (range: 31.8-124.7 kg). Once pigs were weighed, they were individually marked with a unique letter using an animal safe spray paint before being released into the start (home) pen. Facility details are described in Table 1.

| Specifications | Details |

| Site capacity, No. of pigs | 4800 |

| Barn capacity, No. of pigs | 1200 |

| Projected market weight, kg† | 127 |

| No. of barns | 4 |

| Rooms/barn | 1 |

| Barn width, m | 14.9 |

| Barn length, m | 57.9 |

| Pen width, m | 2.8 |

| Pen depth, m | 7.2 |

| Pens/barn | 40 |

| Space allowance, m2 | 0.7 |

| No. pigs/pen | 20-30 |

| Pen flooring | Fully slatted |

| Slat width, cm | 12.7 |

| Slot width, cm | 2.5 |

| Alley flooring | Fully slatted |

| Alley width, cm | 71 |

| Distance from start pen to end pen, m‡ | 20.6 |

* Handling tools used were a sked, revised deer sled, and ice fishing sled.

† Pigs had a mean (SD) body weight of 100 (25.3) kg; range: 125-136 kg.

‡ Two empty pens were designated as the start and end pen.

Epidural procedure

The Swine Medicine Education Center staff and veterinarians at Iowa State University’s College of Veterinary Medicine completed the epidural procedure. Each pig was restrained with a pig snare while standing. Three additional personnel completed the epidural procedure: one supported the pig with a sort board during injection, a second administered the epidural, and a third handed supplies as needed. The injection site was located by palpating the cranial edge of the tuber coxae and finding the point perpendicular to that location on the pig’s midline. The injection site was prepared by shaving the pig’s back and then infiltrated with a local anesthetic agent (Lidocaine 2%; VetOne) prior to insertion of the spinal needle. An 18-gauge, 8.9-cm spinal needle (Becton, Dickinson and Co) was inserted at the prepared location between the last lumbar and first sacral vertebrae. The needle was advanced through the skin, backfat, muscle, and then the fibrous interarticular spinous ligament. The stylet was removed and a 12-mL syringe filled with 2% lidocaine was attached to the needle for administering the anesthetic agent. As the lidocaine was injected, if resistance was noted, the needle was repositioned before administering the full dose; 1 mL/9 kg body weight was administered with a maximum of 12 mL. After administration, the needle was withdrawn and the pig snare removed. The epidural procedure took 6 minutes and the onset of anesthesia occurred within 20 minutes and lasted approximately 2 hours. To monitor the plane of anesthesia and to determine if a pig needed to be removed from the study for humane reasons, pig behavior responses were observed continuously from outside their flight zone and respiration and heart rate were monitored every 15 minutes. Once a pig completed the study, monitoring continued by a swine veterinarian until it was able to stand on all 4 legs and walk.

Handling tool assessment

Using the randomization function in Excel, pigs were randomly assigned to 1 of 3 handling tools. Each handling tool was assigned to 6 individual pigs for a total of 18 pig movement tasks. Employees loaded the nonambulatory pig onto the assigned handling tool and attempted to move the pig from the start pen to the end pen (total distance = 21 m). This distance represented the maximum distance between a home pen and a recovery pen on this farm.

For the sked and revised dear sled, one employee held the handling tool still while the second employee placed the nonambulatory pig onto the handling tool. Both employees secured the pig using the buckle restraint straps. For the ice fishing sled, the handling tool had to be flipped onto its side to allow both employees to place the nonambulatory pig, and then the bottom of the ice fishing sled was set back onto the pen floor. One employee held the pig inside the ice fishing sled, while the second employee secured the pig using 2 buckle restraint straps.

One researcher collected the measurements during the study using a stopwatch: 1) Time (seconds) to place the nonambulatory pig from the start pen floor onto the handling tool. 2) Time (seconds) to secure the nonambulatory pig on the handling tool. 3) Time (seconds) to move the handling tool with the nonambulatory pig from the start to end pen and remove the pig from the handling tool onto the pen floor. 4) Total time (summation of 1, 2, and 3). Handling tool durability was evaluated for presence of holes, rips, and creases at the conclusion of each handling tool movement. If observed, these were counted and measured (centimeters). During each rest period, comments were solicited from the 2 employees to collect qualitative information.

Animal-based assessment

Pig vocalizations and struggling were scored throughout the nonambulatory pig movement tasks. Pig vocalizations were scored as 0 = none, 1 = intermittent grunts/calls, or 2 = continuous grunts/calls.

Pig struggling was scored as 0 = none, 1 = intermittent movement of the legs and head, or 2 = continuous movement of the legs and head.

Pig temperature, respiration rate, and pig assessment were completed before the pig was placed onto the handling tool and once the pig had been removed from the handling tool and was lying on the floor. Pig temperature (°C) was collected via an infrared thermometer (Extech Dual Laser InfraRed Thermometer) and aimed at the pig’s ventral plane. Pig respiration, defined as one inhalation and one exhalation, was counted over 15 seconds by viewing the flank then converted to breaths per minute (bpm). All these measures were collected by one researcher who stayed outside of the pig’s flight zone.

Pig assessment included the number of scratches, defined as disruption of the epidermis and derma that did not penetrate to the subcutaneous and included inflammation; number of bruises defined as injury that included discoloration and inflammation of the skin without exposure of underlying tissues; panting indicated by increased respiration rate and open mouth breathing; muscle tremors indicated by shaking; and skin discoloration defined as blotchy or consolidated cyanosis.

Statistical analysis

All statistical analyses were completed using SAS v 9.2 (SAS Institute, Inc). Time (seconds) to place, secure, move from the start to end pen and remove pig from handling tool, and the total time were dependent variables evaluated using PROC UNIVARIATE. All time variables met the assumption of normality and data was analyzed using mixed model methods (PROC MIXED). The statistical design was a complete randomized design with the fixed effect of handling tool (n = 3), and pig weight (kg) as a linear covariate. Pig vocalization and struggle score data were analyzed using PROC FREQUENCY and CHI SQUARE to evaluate vocalization and struggle score distributions by handling tool. Two new variables, change in pig temperature and respiration rate, were created and were calculated using the following equations:

Change in pig temperature (°C) = end pen nonambulatory pig temperature – baseline pig temperature

Change in pig respiration rate (bpm) = end pen nonambulatory pig respiration rate – baseline pig respiration rate

Changes in pig temperature and respiration rate were evaluated using PROC UNIVARIATE. Pig temperature and respiration rate changes were normally distributed and data were analyzed using mixed model methods (PROC MIXED). The statistical design for pig temperature and respiration rate change was a complete randomized design with the fixed effect handling tool (n = 3), and pig weight (kg) as a linear covariate. All variables were considered significant at P ≤ .05. Pig assessment (number of scratches, bruises, any open mouth breathing, muscle tremors, and skin discoloration) and handling tool durability (presence of creases, holes, or rips) are presented descriptively.

Results

All pigs remained in all phases of the study; no pigs were removed for ethical reasons. No pig assessment concerns were identified premovement. No pigs had any of the aforementioned animal-based measures (scratches, bruises, open mouth breathing, or skin discoloration). Immediately post movement, 4 nonambulatory pigs were observed to have muscle tremors in their front limbs consistent with muscle fatigue and typical of pigs undergoing an epidural. Upon completion of this study, all pigs stood and walked normally on 4 legs, after which time they were returned to their home pens.

Time to place the nonambulatory pig from the start pen floor onto the handling tool, to secure the nonambulatory pig on the handling tool, and total time was not affected by the handling tool (P ≥ .12). There was a trend for time to move the handling tool with the nonambulatory pig from the start to end pen, which included removing the pig from the handling tool and placing them onto the end pen floor (P = .06; Table 2).

| Handling tool | P value* | |||

|---|---|---|---|---|

| HMH sked rescue system | Revised deer sled | Ice fishing sled | ||

| Time to complete handling task, mean (SD), s† | ||||

| Place | 9 (10.2) | 28 (10.0) | 38 (10.0) | .16 |

| Secure | 24 (3.9) | 26 (3.9) | 15 (3.9) | .12 |

| Start to end | 106 (18.3) | 121 (18.0) | 58 (17.9) | .06 |

| Total | 139 (20.6) | 175 (20.2) | 115 (20.2) | .14 |

| Respiration rate change, mean (SD), bpm‡ | 11.0 (3.9) | 7.0 (3.8) | 10.0 (3.8) | .81 |

| Body temperature change, mean (SD), °C‡ | 0.8 (1.4) | 1.9 (1.4) | 2.5 (1.4) | .71 |

* All statistical analyses were completed using SAS v 9 using mixed model methods (PROC MIXED). All variables were considered significant at P ≤ .05.

† Time to place the nonambulatory pig from the start pen floor onto the handling tool. Time to secure the nonambulatory pig on the handling tool. Time to move the handling tool with the nonambulatory pig from the start to end pen and remove the pig from the handling tool onto the pen floor. Total time was the summation of time to place, secure, and start to end.

‡ Two new variables, change in pig temperature and respiration rate, were created and were calculated using the following equations:

Change in pig temperature (°C) = end pen nonambulatory pig temperature – baseline pig temperature.

Change in pig respiration rate (bpm) = end pen nonambulatory pig respiration rate – baseline pig respiration rate.

Bpm = breaths per minute.

The ice fishing sled was the most durable with no creases, rips, or holes. The HMH sked rescue system developed 2 creases. The first crease occurred during the first pull and was 1.3 cm in length. The second crease occurred during the sixth (final) pull and was 7.6 cm in length. The revised deer sled developed 2 creases. The first crease occurred during the third pull and was 2.5 cm in length. The second crease occurred during the fourth pull and was 20.3 cm in length.

There were no handling tool differences for pig vocalization or struggle scores when placing a nonambulatory pig from the start pen floor onto the handling tool, securing the nonambulatory pig onto the handling tool, moving the nonambulatory pig on the assigned handling tool from the start to end pen, and removing the nonambulatory pig from the handling tool onto the end pen floor (P > .10; Table 3). Change in pig respiration rate and body temperature did not differ between handling tools (P ≥ .71; Table 2).

| Handling tool, No. of pigs (%) | |||

|---|---|---|---|

| HMH sked rescue system | Revised deer sled | Ice fishing sled | |

| Vocalization score when placed onto the handling tool | |||

| 0 | 5 (27.8) | 2 (11.1) | 1 (5.6) |

| 1 | 1 (5.6) | 3 (16.7) | 2 (11.1) |

| 2 | 0 (0) | 1 (5.6) | 3 (16.7) |

| Struggle score when placed onto the handling tool | |||

| 0 | 2 (11.1) | 3 (16.7) | 3 (16.7) |

| 1 | 4 (22.2) | 2 (11.1) | 1 (5.6) |

| 2 | 0 (0) | 1 (5.6) | 2 (11.1) |

| Vocalization score when securing pig onto the handling tool | |||

| 0 | 5 (27.8) | 2 (11.1) | 2 (11.1) |

| 1 | 1 (5.6) | 4 (22.2) | 4 (22.2) |

| 2 | 0 (0) | 0 (0) | 0 (0) |

| Struggle score when securing pig onto the handling tool | |||

| 0 | 5 (27.8) | 2 (11.1) | 3 (16.7) |

| 1 | 1 (5.6) | 3 (16.7) | 3 (16.7) |

| 2 | 0 (0) | 1 (5.6) | 0 (0) |

| Vocalization score when moving the pig from the start to end pen and removal from the handling tool | |||

| 0 | 6 (33.3) | 4 (22.2) | 3 (16.7) |

| 1 | 0 (0) | 2 (11.1) | 3 (16.7) |

| 2 | 0 (0) | 0 (0) | 0 (0) |

| Struggle score when moving the pig from the start to end pen and removal from the handling tool | |||

| 0 | 5 (27.8) | 4 (22.2) | 5 (27.8) |

| 1 | 1 (5.6) | 2 (11.1) | 1 (5.6) |

| 2 | 0 (0) | 0 (0) | 0 (0) |

* Pig vocalizations and struggling were scored throughout the movement tasks. Pig vocalization scores were 0 = none, 1 = intermittent grunts/calls, or 2 = continuous grunts/calls. Pig struggling scores were 0 = none, 1 = intermittent movement of the legs and head, or 2 = continuous movement of the legs and head. Handling tools did not differ (P > .10).

† One commercial grow-finish site was used and building and production specifications are provided in Table 1. The sked, revised deer sled, and ice fishing sled each moved 6 different nonambulatory pigs on farm.

Discussion

The objective of this study was to evaluate an HMH sked rescue system, revised deer sled, and ice fishing sled as humane handling tools for moving nonambulatory pigs on a commercial wean-to-finish farm. Anderson et al7 defined a nonambulatory pig as a pig that is “unable to move or keep up with its contemporaries at the processing plant.” Ellis and Ritter8,9 delineated the nonambulatory pig into 2 categories: 1) fatigued is a pig that is without obvious injury, trauma, or disease and refuses to walk or keep up with their contemporaries at any stage of the marketing process and 2) injured is a pig that displays a compromised ability to ambulate because of structural unsoundness or an injury sustained before or during the marketing process. During the marketing process, approximately 80% of pigs that become nonambulatory are in a state of metabolic acidosis and are classified as fatigued, yet the majority of these pigs will recover fully if given time to rest.10 The proportion of nonambulatory pigs on farm that recover is unknown.

Although national statistics are not available for the incidence of nonambulatory pigs, a review by Ritter et al10 reported an incidence rate of 0.63% for nonambulatory pigs during marketing. Before the current study was initiated, a total of 6370 finishing pigs were observed during the marketing process on 5 wean-to-finish farms. However, only one naturally occurring nonambulatory pig was observed (0.002%). Therefore, waiting for naturally occurring nonambulatory incidences on farm was ineffective.

A novel nonambulatory pig biomedical model was created; this was an unplanned but significant outcome of the study. Because of the multiple and varied pathways that might lead to a naturally occurring nonambulatory animal, any consistent, controlled, and repeatable model was likely to imperfectly represent one or more natural causes. However, consistent with the principles of the 3 R’s, this nonambulatory pig biomedical model strategy allowed for relative comparison of candidate devices with less animal impact by lowering the number of test repetitions necessary to draw conclusions. The epidural procedure affected the motor functions of the hind limbs and resulted in recumbency, therefore, mimicking a nonambulatory pig. It also eliminated the potential to exacerbate pain associated with a naturally occurring cause of nonambulatory status. After viewing vocalization and struggle score results, we question if the epidural procedure inadvertently lowered these scores. Epidural anesthesia refers to the sensory, motor, and autonomic blockade produced by epidural administration of local anesthetics. Lidocaine was used as the local anesthetic and administered into the lumbosacral epidural space, which produced a rapid desensitization of the caudal portions of the abdominal cavity, inguinal area, hind limbs, tail, and perineum.11 Studies on horses,12 dogs,13 cattle, buffalo, and camels14 have shown the effectiveness of spinal sensory blocks for pain control on the chronically ill and during surgical procedures. Naturally occurring nonambulatory pigs may become overwhelmed by the accumulation of stressors, including pain, and collapse, but may still have sensory function in their hind legs. Pigs used in the study may have had less of a vocalization and struggle reaction when employees were attempting to load and move the pigs onto the handling tools because of too little or lack of sensation in their hind limbs. The immobility and loss of sensation using this model infers that devices which were difficult to use in this study would certainly be expected to fail if the animal was able to move and resist with the hind legs.

Respiration rates increased in all groups and, given the lack of behavioral indicators of stress, may reflect the rising ambient temperature of the facility during the progression of the day. Pig temperatures differed by up to 2.5°C, but were not interpreted as indicators of stress because absolute values did not extend outside the normal range for the age, weight, and environment of the pigs. Most pigs were roused for the study from a resting period on cool concrete allowing for increases that did not exceed the upper limit of the normal range.

Field expertise associated with moving nonambulatory pigs has resulted in several guidance documents. The American Meat Institute recommends using slide boards, sleds, and “cripple carts” to move nonambulatory pigs within meat processing plants.15 Similarly, the TQA program recommends stretchers, sleds, hand carts, and specialized skid loaders for moving nonambulatory pigs.2 When nonambulatory pigs occur on farms, the PQA Plus program recommends using plastic sleds or drag mats.1 Our previous 2 studies compared handling tools to move grow-finish pig cadavers. The first study did not support the use of a modified wean-to-finish mat as a suitable handling tool for manually moving grow-finish pigs. Although the second study did not support the use of a modified deer sled, it did support the use of a sked and deer sled.4-6

When comparing placing a pig onto the handling device, the HMH sked rescue system was the fastest (9 seconds) with the ice fishing sled taking an additional 29 seconds. Securing a pig was quickest on the ice fishing sled (15 seconds) with the revised deer sled taking the longest (an additional 11 seconds). There was a trend for the ice fishing sled to move from the start to end pen more quickly (58 seconds) compared to the other 2 handling tools, with the revised deer sled taking an additional 63 seconds. While there was no difference between the 3 handling tools for the total time needed to move between the start and end pens, these results should be interpreted with caution. The time to move from point A to point B are likely dependent on the farm. Grow-finish barn designs can vary by barn layout, differing alleyway width and length, pen and alley flooring, and percentage of dry vs wet manure covering the floor.

All handling tools were durable, with only 2 creases that developed for both the HMH sked rescue system and the revised deer sled. These creases did not cause injury to the pigs, nor did they impair the handling tool functionality.

After study completion, the 2 employees provided a summary describing the strengths and weakness of each handling tool. When moving the nonambulatory pig from the start pen floor onto the handling tool, both employees commented on how the sked’s thicker material made loading easier compared to the other 2 handling tools. The flimsiness of the revised deer sled made this process more difficult. As the nonambulatory pigs were moved from the floor into the revised deer sled, some pigs struggled causing the employees to stop and re-adjust both the handling tool and pig. The ice fishing sled was the most difficult handling tool to move the nonambulatory pig from the start pen floor onto the handling tool because 2 employees were required to successfully complete this task. One employee commented that even when the ice fishing sled was tipped on its side this task was difficult to complete, especially if the pigs struggled. These comments are supported when considering the mean time needed to move the nonambulatory pig from the start pen floor onto the handling tools: sked (9 seconds) vs revised deer sled (28 seconds) vs ice fishing sled (38 seconds).

During the moving process, employees commented that the sked’s stiff material would sometimes catch on gates causing sked readjustments, which prevented a smooth forward transition. Depending on the angle from the start pen to alley entrance, or conversely the alley to end pen entry, it was at times difficult to turn the sked. Both employees supported the sked handle placement and remarked that the sked pulled more evenly than the revised deer sled. For the revised deer sled, the material was easier to manipulate and the restraints worked well and could be adjusted so that the pig was safely cocooned inside. The ice fishing sled had the smoothest transition when moving from the start to the end pen. A negative to the ice fishing sled was related to its smaller size where it was noted that a heavier pig may not fit well onto this handling tool. These comments are supported by comparing the mean duration to move from the start pen to the end pen (ice fishing sled [58 seconds] vs revised deer sled [121 seconds]). Another susceptible animal group are those that cannot ambulate when injured. If the caretaker ethically determines that the prognosis of recovery is high, they may need to move this injured pig. It is hypothesized that these handling tools show promise and it would be prudent to test them with injured pigs on farm.

The purpose of this study was to determine if the sked, revised deer sled, and ice fishing sled could be suitable handling tools to move live nonambulatory pigs on farm. This novel study demonstrates that these 3 handling tools are suitable for on-farm movement of a nonambulatory pig. Pigs were easy to secure, they did not struggle and vocalize, and the caretaker could move them quickly. These tools could be considered for inclusion in both the PQA Plus and TQA programs as humane handling tool options for nonambulatory pigs on farm.16,17

Implications

Under the conditions of this study:

- Pigs were easy to secure, did not struggle, and had minor physiological changes.

- All 3 handling tools were humane options to move nonambulatory grow-finish pigs.

- All 3 handling tools should be considered for the US industry’s programs.

Acknowledgments

Iowa Pork Producers Association supported this work. Support from the Department of Animal Science, College of Agriculture and Life Sciences at Iowa State University and the US Department of Agriculture for partial funding of Dr Johnson’s salary. The authors would also like to thank Iowa Select Farms for the use of the farm site and 2 employees for their assistance in data collection. Thank you to the Swine Medicine Education Center at Iowa State University College of Veterinary Medicine for their assistance in the epidural procedure.

Conflict of interest

None reported.

Disclaimer

Scientific manuscripts published in the Journal of Swine Health and Production are peer reviewed. However, information on medications, feed, and management techniques may be specific to the research or commercial situation presented in the manuscript. It is the responsibility of the reader to use information responsibly and in accordance with the rules and regulations governing research or the practice of veterinary medicine in their country or region.

References

* 1. National Pork Board. Pork Quality Assurance Plus Handbook. Version 3. Published June 2016. Accessed January 1, 2018. https://d3fns0a45gcg1a.cloudfront.net/sites/all/files/documents/PQAPlus/V3.0/BinderMaterial/Tab%202/1%20PQAhandbook.pdf

*2. National Pork Board. Transport Quality Assurance Handbook. Version 6. Published 2017. Accessed September 14, 2017. https://d3fns0a45gcg1a.cloudfront.net/sites/all/files/documents/TQA/2017-Version6/TQA.V6_Handbook.pdf

*3. National Pork Board. Common Swine Industry Audit. Published 2019. Accessed February 5, 2018. http://d3fns0a45gcg1a.cloudfront.net/sites/all/files/documents/CommonSwineIndustryAudit/CSIA-English.pdf

4. Akin EE, Johnson AK, Ross JW, Millman ST, Jass CD, Stinn JP, Stalder KJ. Modified wean-to-finish mat as an alternative handling tool for moving grow-finish pig cadavers: A pilot study. J Swine Health Prod. 2019;27(5):278-283.

5. Akin EE, Johnson AK, Millman ST, Jass CD, Stalder KJ, Stinn JP, Ross JW. Alternative handling tools for moving grow-finish pig cadavers. J Swine Health Prod. 2020;28(3):125-134.

6. Akin EE. Handling tools to move non-ambulatory pigs that comply with the Common Swine Industry Audit. Pork Information Gateway. PIG 05-02-02. Published September 2019. Accessed August 8, 2022. http://porkgateway.org/resource/handling-tools-move-non-ambulatory-pigs-comply-common-swine-industry-audit/

*7. Anderson DB, Ivers DJ, Benjamin ME, Gonyou HW, Jones DJ, Miller KD, McGuffey RK, Armstrong TA, Mowrey DH, Richardson LF, Seneriz R, Wagner JR, Watkins LE, Zimmermann AG. Physiological responses of market hogs to different handling practices. In: Proceedings of the 33rd AASV Annual Meeting. American Association of Swine Veterinarians; 2002:399.

*8. Ellis M, Ritter M. Impact of animal handling and transportation conditions on losses of slaughter weight swine during transport. In: Proceedings of the 36th AASV Annual Meeting. American Association of Swine Veterinarians; 2005:199.

*9. Ellis M, Ritter M. Transport losses: Causes and solutions. In: Proceedings of the Allen D. Leman Swine Conference. University of Minnesota; 2005:176.

10. Ritter MJ, Yoder CL, Jones CL, Carr SN, Calvo-Lorenzo MS. Transport losses in market weight pigs: II. U.S. incidence and economic impact. Transl Anim Sci. 2020;1103-1112. https://doi.org/10.1093/tas/txaa041

11. Cruz ML, Luna SPL, Clark RMO, Massone F, Castro GB. Epidural anaesthesia using lignocaine, bupivacaine or a mixture of lignocaine and bupivacaine in dogs. J Vet Anaesth. 1997;24:30-32. https://doi.org/10.1111/j.1467-2995.1997.tb00265.x

12. Natalini CC. Spinal anesthetics and analgesics in the horse. Vet Clin North Am Equine Pract. 2010;26:551-564. https://doi.org/10.1016/j.cveq.2010.07.005

13. Steagall P, Simon BT, Teixeira Neto FJ, Luna S. An update on drugs used for lumbosacral epidural anesthesia and analgesia in dogs. Front Vet Sci. 2017;4:68. https://doi.org/10.3389/fvets.2017.00068

14. Ismail ZB. Epidural analgesia in cattle, buffalo, and camels. Vet World. 2016;9:1450-1455. https://doi.org/10.14202/vetworld.2016.1450-1455

15. Grandin T, American Meat Institute Animal Welfare Committee. Recommended animal handling guidelines & audit guide: A systematic approach to animal welfare. 2013. Accessed August 8, 2022. http://gpvec.unl.edu/Elective_files/feedlot/Animal_Handling_Guidelines_AMI_May2103.pdf

16. Hill J, Berry N, Johnson AK. Handling and loadout of the finisher pig. Pork Information Gateway. PIG 09-08-02. Published July 2007. Accessed January 1, 2018. http://porkgateway.org/resource/handling-and-loadout-of-the-finisher-pig

17. Johnson AK, Gesing LM, Ellis M, McGlone JJ, Berg E, Lonergan SM, Fitzgerald R, Karriker LA, Ramirez A, Stalder KJ, Sapkota A, Kephart R, Selsby JT, Sadler LJ, Ritter MJ. Farm and pig factors affecting welfare during the marketing process. J Anim Sci. 2013;91:2481-2491. https://doi.org/10.2527/jas.2012-6114

* Non-refereed references.

PDF version

PDF version RIS

citation

RIS

citation