| Production tool | Peer reviewed |

Cite as: Rice M, Baird C, Stikeleather L, et al. Carbon dioxide system for on-farm euthanasia of pigs in small groups. J Swine Health Prod. 2014;22(5):248–254.

Also available as a PDF.

SummaryCertain swine-farm operations require the regular euthanizing of multiple pigs on almost a daily basis. These animals may be too large for the small-scale methods of euthanasia used for nursing pigs and therefore may require the use of individual mechanical methods approved by the American Veterinary Medical Association (AVMA), such as gunshot and captive bolt. These methods may be unpleasant for workers and pose additional handling and carcass-disposal challenges. Considerable research has been done using the AVMA-recommended carbon dioxide (CO2) method for mass depopulation of swine in the case of an exigent situation. This paper details a method for adapting that CO2 methodology for euthanizing small groups of pigs. The system does not require direct worker contact with individual animals or manual handling of carcasses. The concept involves use of a standard high-pressure CO2 cylinder and a small euthanasia chamber, which can be a small dump-type trailer to allow easy transport to a disposal site. A detailed description of the CO2 application system and method is provided so that producers can construct a suitable system from readily available low-cost components. | ResumenCiertos sistemas porcinos requieren la eutanasia regular de múltiples cerdos casi a diario. Estos animales pueden ser muy grandes para ser sacrificados mediante los métodos de eutanasia a pequeña escala utilizados para cerdos en destete y por lo tanto pueden requerir el uso de métodos mecánicos individuales aprobados por la Asociación Americana Médica Veterinaria (AVMA por sus siglas en inglés), tales como un disparo y la bala cautiva. Estos métodos pueden ser desagradables para los trabajadores y pueden crear problemas adicionales de manejo y eliminación de la canal. Se ha realizado una investigación exhaustiva utilizando el método de dióxido de carbono (CO2) recomendado por el AVMA para la despoblación masiva en el caso de una situación apremiante. Este documento detalla un método para adaptar esa metodología de CO2 para la eutanasia de pequeños grupos de cerdos. El sistema no requiere el contacto directo del trabajador con los animales de manera individual o el manejo manual de las canales. El concepto incluye el uso de un cilindro estándar de CO2 de alta presión y una pequeña cámara de eutanasia, que puede ser un pequeño furgón de descarga para permitir el fácil transporte a un sitio de desecho. Se provee una descripción detallada del método y sistema de aplicación del CO2, para que los productores puedan construir un sistema adecuado con componentes de bajo costo ya disponibles. | ResuméIl est nécessaire sur certaines fermes porcines de procéder à l’euthanasie régulière de plusieurs porcs presque sur une base quotidienne. Ces animaux peuvent être trop gros pour les méthodes d’euthanasie à petite échelle utilisées pour les porcs en pouponnière et ainsi peuvent nécessiter l’utilisation de méthodes mécaniques approuvées par l’American Veterinary Medical Association (AVMA), telles que l’arme à feu et le percuteur. Ces méthodes peuvent être déplaisantes pour les travailleurs en plus de poser des défis supplémentaires en ce qui concerne des manipulations supplémentaires et la disposition des carcasses. De nombreuses recherches ont été effectuées sur la méthode recommandée par l’AVMA d’utilisation du dioxyde de carbone (CO2) pour une dépopulation massive de porcs dans un cas où la situation l’exige. Cet article décrit une méthode pour adapter la méthode au CO2 afin d’euthanasier des petits groupes de porcs. Le système ne nécessite pas de contact direct de l’employé avec des animaux individuellement ou la manutention de carcasses. Le concept implique l’utilisation d’un cylindre standard de CO2 sous haute pression et une petite chambre à euthanasie, qui peut être du type petite remorque à bascule pour permettre le transport facile à un site de disposition des carcasses. Une description détaillée du système à CO2 et de la méthode à utiliser sont fournies afin de permettre aux producteurs de construire un système approprié à l’aide de composantes disponibles et peu coûteuses. |

Keywords: swine, euthanasia, carbon dioxide, AVMA, on-farm

Search the AASV web site

for pages with similar keywords.

Received: November 4, 2013

Accepted: February 11, 2014

Safety advantages of CO2

Safe, humane, and practical methods for euthanizing small groups of swine are important to the pork industry and to farm personnel. Carbon dioxide offers the potential for meeting overall humane and safety requirements. For example, use of CO2 does not require restraint of individual pigs or application of mechanical means that can be hazardous and stressful for personnel.3 Application of CO2 allows for pigs to be treated in groups rather than individually. Minimizing the number of workers required simplifies personnel training. It is well established that CO2 results in rapid depressant, analgesic, and anesthetic effects. Concentrations of CO2 < 30 volume percent are seemingly not aversive to pigs.4,5 Carbon dioxide produces quicker loss of consciousness than inert gas hypoxia when administered by gradual displacement methods,6 and gradual displacement administration of CO2 is less likely to cause pain due to ocular and nasal nociceptor activation prior to loss of consciousness.1 Further, when CO2 is gradually administered to young pigs at a constant displacement rate of either 10% or 20% of the container volume per minute, unconsciousness occurs within 80 to 124 seconds at approximately 22 volume percent CO2 concentration, and the increase in plasma concentrations of cortisol, norepinephrine, and lactate after exposure to CO2 do not differ from those observed following the physical methods of captive bolt and electrocution.6 Unlike nitrogen and argon, which must be held within a very tight range of concentration to reduce oxygen (O2) levels below 2% of the total volume for effective killing, CO2 can render pigs unconscious and kill over a wide range of concentrations, even when O2 is greater than 2% of the total volume.7 Meyer and Morrow2 point out that other advantages of CO2 as a euthanasia agent include its ready availability and relatively low cost, its nonflammable and non-explosive properties, and the rapid reversal of its toxic effects after accidental exposure of personnel by prompt removal from the area (unlike other gases such as carbon monoxide). Carbon dioxide poses minimal hazard when used with properly designed equipment.2

CO2 system requirements

The main components of a CO2 system for on-farm euthanasia of small batches of pigs can be listed as follows: a small euthanasia chamber with no air leaks in floor or sides; a translucent cover for the chamber, such as a clear polyethylene film secured but not sealed to the top edges of the chamber walls; a hose or pipe for delivery of the CO2 to the floor area of the chamber; a means for delivering CO2 to the euthanasia chamber so that a volume of CO2 equal to the volume of the chamber can be delivered in a total of 5 minutes; and a method of supplying and metering this amount of CO2. This paper will recommend a method which allows use of a high-pressure CO2 cylinder of standard size (22.2 kg, or other size as desired) and a low-cost means for storing and metering the required amount of CO2 gas for each euthanasia treatment.

The euthanasia chamber (dump-type trailer)

The euthanasia chamber should be sized to hold pigs of the anticipated size and number. Transport density recommendations can be used to estimate the required chamber size.8 The height of the chamber walls should allow adequate head room for the pigs. Excessive height should be avoided, since that space will require additional CO2 volume. The floor and walls of the chamber must be airtight. If the euthanasia chamber is to be mobile and used as a dump-trailer body, the tailgate should be hinged to allow for convenient dumping. A smaller sliding or hinged doorway will facilitate the movement of pigs from the loading chute into the trailer. A sliding door such as that shown in Figure 1 allows the door to be opened without interfering with the loading chute or other obstructions.

Figure 1: A standard dump trailer or truck modified for use as a swine euthanasia chamber. A sliding tailgate section and top hinges added to this truck bed facilitates loading of live pigs and then dumping the carcasses once the pigs have been euthanized. The sides and tailgate are sealed with expanding foam to form a gas-tight seal. A tarpaulin or plastic sheeting is placed over the truck bed to reduce air mixing and carbon dioxide washout.

The euthanasia chamber cover

The top of the chamber can be covered with a clear or translucent polyethylene sheet secured with tape. The clear or translucent material is recommended to avoid having a dark space that pigs do not want to enter. The interface between the cover and the top edges of the side walls need not be airtight: in fact, there needs to be some air leakage at the top to allow for air to purge out of the space during CO2 wash-in. This cover can be left on the chamber at all times, but prior to each use, it should be checked to confirm that it is well secured and in good condition. If damaged, it must be replaced prior to the next CO2 treatment.

Delivery of CO2 into the euthanasia chamber

Carbon dioxide should be delivered to the chamber via a hose or flexible pipe, preferably 2.5 to 7.6 cm in diameter, inserted through the top cover and extending down to within 5.1 to 7.6 cm of the floor. The larger the hose diameter, the lower the CO2 gas exit velocity and the lower the noise, turbulence, and mixing of CO2 and air. The hose may be placed near one of the side walls, preferably near the mid-span of the wall, although this is not critical. The CO2, which is heavier than air, will diffuse and fill the chamber from the floor to the top. Studies have shown that distribution manifolds are not needed to get uniform CO2 distribution in the chamber.9

The CO2 storage and metering system

Figure 2 shows a schematic of the component arrangement. The model euthanasia chamber, shown in Figure 3, was a dump trailer with a volume of approximately 1.7 m3 (1.8 m wide × 1.2 m long × 0.8 m high). The CO2 delivery system must be capable of supplying 20% of the chamber volume per minute during the 5-minute application period. In 5 minutes, the system delivers a volume of CO2 equal to the chamber volume, meeting the AVMA guideline.1 For large euthanasia-chamber volumes, the standard high-pressure CO2 cylinder may not supply the required flow rate directly to the chamber, because the high CO2 gas outflow could cause freeze-up in the CO2 cylinder regulator and distribution line. Multiple cylinders could be connected in parallel using a manifold, but this adds an undesirable degree of complexity. The illustrated design uses one standard high-pressure CO2 cylinder with a standard pressure regulator that can be set and locked to the required pressure, allowing the low-pressure tank to fill at a rate slow enough to avoid line freeze-up. The suggested scenario is that the storage tank refills immediately after each euthanasia treatment, allowing enough time for the CO2 gas to approach ambient temperature prior to the next treatment. The required pressure depends on the volume of the low-pressure CO2 tank and the euthanasia-chamber volume being serviced. As shown in Figure 2, the pressure regulator is used to pre-charge the low pressure tank to ensure there is adequate CO2 to perform the euthanasia. The low-pressure tank is then allowed to empty into the euthanasia chamber through a quarter-turn valve and orifice sized to allow the tank to bleed down to atmospheric pressure in 5 minutes. Our low-pressure CO2 tank was a recycled 1000-L liquid petroleum (LP) gas tank with the original LP fittings removed. The LP tank was chosen because of its adequate pressure rating and availability and because it was configured with the necessary ports needed for the CO2 gas connections. If some other type of tank is used, it must be rated for the pressures that will be required to store the CO2.

Figure 2: Block diagram of a CO2 application system for releasing high-pressure CO2 into a low-pressure tank for application as a swine euthanasia chamber as described in Figure 1. The CO2 is released slowly into the low-pressure tank through a pressure regulator to avoid tank and regulator freezing. When the low-pressure tank has reached the predetermined pressure set by the regulator, the valve to the euthanasia chamber is opened, allowing the orifice to control CO2 flow into the chamber. This flow rate must meet the American Veterinary Medical Association guidelines for use of CO2 for euthanizing pigs. A pressure-relief valve with a pressure rating slightly above the required pressure, and well below the maximum tank pressure rating, should be used to avoid over-pressurizing the low-pressure tank. The pressure regulator maintains the preset pressure in the low-pressure tank between application events.

Figure 3: A prototype CO2 application system assembled and used to verify the performance of the swine euthanasia system illustrated and described in figures 1 and 2. A pressure-relief valve has been added to a used propane tank to serve as the low-pressure CO2 tank. An orifice plate (Figure 4) was included in the discharge hose to control the CO2 gas flow into the dump trailer used as a model euthanasia chamber.

Initial purging of the low-pressure CO2 tank

The low-pressure tank is purged of air and residual LP gas fumes by filling it several times with CO2 while allowing the gases in the tank to bleed out of the top ports. This initial purging can be enhanced by fabricating a CO2 inlet tube to carry the incoming CO2 to the bottom of the tank, allowing the CO2 to displace the air and any other gases with a minimum of mixing. An alternate approach to initial purging is to place in the tank approximately 2 kg of dry ice pellets or chips per cubic meter of tank volume so that the CO2 gas from sublimation will purge the tank of air and other gases.

Calculating the pressure required for the low-pressure CO2 tank

Initially, the low-pressure tank must be filled with enough CO2 gas so that when it flows to the euthanasia chamber and equilibrates (after 5 minutes) to atmospheric pressure, the volume of CO2 released to the chamber will be equal to the volume of the chamber. In order to calculate the initial pressure required in the low-pressure tank we apply the ideal gas law which says

P1V1 = P2V2 (Equation 1)

P1 = P2V2 ÷ V1 (Equation 2)

where P1 and P2 are absolute pressures.10 In the described swine euthanasia system, P1 is the pressure required in the low-pressure tank; P2 is atmospheric pressure, 105 Pascal (Pa); V1 is the volume of the low-pressure tank, in this case approximately 1.0 m3; and V2 is the total volume occupied by the CO2 after it expands. Then V2 is the volume of the storage tank plus the volume of the chamber. The size of the model euthanasia chamber was 1.7 m3, which gives a total V2 volume of 1.0 +1.7 = 2.7 m3.

Equations 1 and 2 allow us to compute the initial pressure required in the low-pressure CO2 tank. P1 = (105 × 2.7) ÷ 1.0 = 270 kPa absolute pressure or approximately 170 kPa gauge pressure.

Equations 1 and 2 assume a constant temperature expansion that is not really the case. There will be a temperature decrease due to the expansion of the CO2. However, our calculations, applying the ideal gas law,10 indicate that at these low pressures, the temperature change is < 0.2°C. Increasing this computed pressure by approximately 10%, which in this case would bring the gauge pressure P1 to about 187 kPa, provides a safety factor to compensate for a pressure difference due to changes in temperature and other system variables. This should account for the loss of pressure that may occur and ensures that there will be enough CO2 to meet AVMA guidelines. This was verified during our testing by measuring the change in weight of the high-pressure CO2 cylinder before and after pressurizing the low-pressure tank (when the tank initially contained CO2 at atmospheric pressure). Since CO2 gas at 20°C and one atmosphere occupies approximately 0.55 m3 per kg, approximately 3.1 kg of CO2 was required for a 1.7-m3 chamber.

If a low-pressure storage tank of a different size is chosen, the pressure appropriate for that tank must be computed. For example, for a 0.6-m3 low-pressure tank used with a 1.7-m3 euthanasia chamber (the same size as the model), this would work out to P1 = 383 kPa absolute pressure or approximately 283 kPa gauge pressure. Adding the 10% safety factor as recommended, the required gauge pressure is approximately 311 kPa for a 0.6-m3 low-pressure tank to supply a euthanasia chamber with a volume of 1.7 m3.

Orifice for setting the flow rate

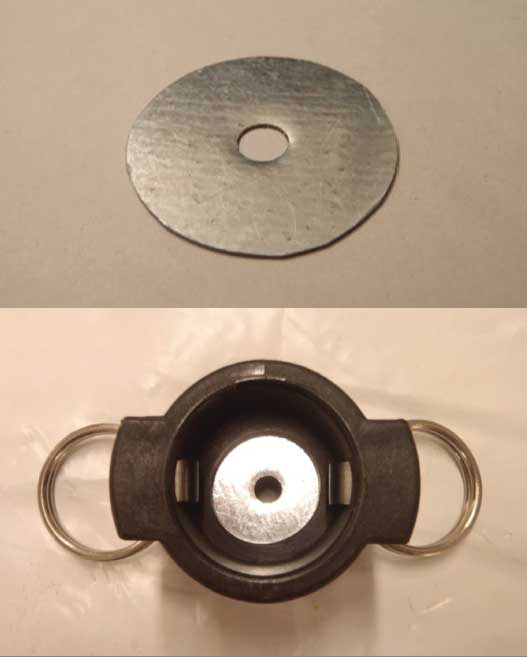

In the hose or pipe connecting the low-pressure tank to the euthanasia chamber, there must be a metering orifice sized to allow the CO2 gas in the low-pressure tank to expand into the euthanasia chamber at the rate of approximately 20% of the chamber volume per minute. This means the orifice should allow the low-pressure tank to reach atmospheric pressure in 5 minutes once the valve to the euthanasia chamber is opened, allowing gas flow to begin. In this model, a fixed orifice was fabricated by drilling a hole in a disk of 0.95 mm thick stainless steel sheet metal (Figure 4). For the 1000-L storage tank and 1.7-m3 chamber, an orifice hole of 0.67-cm diameter was needed to provide a 5-minute bleed-down time. Figure 5 shows typical test data for gauge pressure, % CO2, and % O2 versus time in seconds.

Figure 4: An orifice plate inserted into the tank fitting to control the flow of CO2 from the low-pressure tank to the chamber in the swine euthanasia system illustrated and described in Figure 2. The top figure is the orifice plate made of 0.95 mm thick stainless steel sheet metal. The bottom figure shows the orifice plate mounted in the quick-connect coupling used to connect the low-pressure tank to the chamber shown in Figure 3.

Figure 5: Typical data showing the changes in the low-pressure storage tank pressure, CO2 concentration, and O2 concentration in a model swine euthanasia chamber over time. The pressure in the tank decreases as the CO2 flows into the chamber through an orifice plate. As the CO2 flows into the chamber, CO2 concentration increases and the air is displaced, reducing O2 concentration.

Practical application

The CO2 system described can be easily constructed for use on-farm. Table 1 contains a list of materials used for the prototype system. The high-pressure CO2 cylinder and pressure gauges should be stored inside a building for security and protection from weather. There should be easy access for convenient cylinder exchange, which may occur frequently depending on usage. For example, since the 1.0-m3 chamber requires approximately 3.1 kg of liquid CO2 per treatment cycle, a standard 22.2-kg, high-pressure CO2 cylinder should provide about seven treatments before the pressure becomes too low to recharge the low-pressure tank. The overall concept allows the use of CO2 without sophisticated controls or skilled personnel. Steps for use are essentially as follows.

Table 1: List of materials required to construct a carbon dioxide gas swine euthanasia system

| Item description | Vendor | Part no. |

|---|---|---|

| 22.2 kg high-pressure CO2 cylinder* | Air Gas, Radnor, PA | CD 50 |

| Compressed-gas pressure regulator† | Air Gas, Radnor, PA | HCL3000540 |

| Pressure regulator adapter, CGA320 to CGA580‡ | Air Gas, Radnor, PA | RAD64003956 |

| Safety pressure-relief valve§ | McMaster-Carr, Atlanta, GA | 48435K81 |

| Pressure gauge¶ | McMaster-Carr, Atlanta, GA | 4000K721 |

| Used LP gas tank used for low-pressure CO2 storage** | NA | NA |

| Pneumatic hose, gas regulator to storage tank†† | Lowe’s, Wilkesboro, NC | Various lengths |

| Pneumatic coupler set, quick connect, two sets needed‡‡ | Lowe’s, Wilkesboro, NC | 235470 |

| Orifice to control low-pressure CO2 flow | Fabricate | NA |

| Ball valve, 1-1/4-inch NPT, full port§§ | Lowe’s, Wilkesboro, NC | 369200 |

| Hose leading to chamber¶¶ | Agri Supply, NC | 18415 |

| Plastic film, clear, 6 mil*** | Agri Supply, NC | 11424 |

* Tank size and vendor optional.

† CO2-N2 compatible regulator.

‡ CO2 gas cylinder to compatible gas regulator.

§ Pressure set above desired tank pressure but well below tank-rated pressure.

¶ 0-60 psi range adequate.

** 250-gallon (950 L).

†† Pressure rated, ¼-inch NPT ends, use shortest available length. NPT = National Pipe Thread.

‡‡ Make connections more convenient.

§§ Should not restrict flow when wide open.

¶¶ Hose should be 2.45-5.08 cm ID to allow low-velocity CO2 flow.

*** Polyethylene sheeting for euthanasia chamber, various sizes.

CO2 = carbon dioxide gas; N2 = nitrogen gas; LP = liquid petroleum; NA = not applicable; NPT = National Pipe thread.

First the high-pressure CO2 regulator is set to the required pressure. In the prototype system, that pressure is 187 kPa. This allows a low flow rate of CO2 from the high-pressure cylinder, continuing until the low-pressure tank reaches 187 kPa. This can be the normal state, which means that any time a chamber or trailer load of pigs is to be euthanized, the CO2 is ready for application. Once the euthanasia chamber is located near the low-pressure tank and the delivery hose is inserted into chamber with the end of the hose approximately 5.1 to 7.6 cm above the floor of the chamber, the ball valve on the outlet of the low-pressure CO2 tank can be fully opened and the orifice will control the flow to fill the chamber in approximately 5 minutes. Flow rate is not constant with this arrangement, but the average is approximately 20% of the chamber volume per minute, which is what AVMA requires. Once the low-pressure CO2 tank bleeds down to zero gauge pressure, the ball valve is closed, allowing the tank to refill over a period of time so that it will be ready for the next application. At this point, the CO2 hose can be pulled out of the chamber and the cover re-secured in that spot. As a final step, the euthanasia chamber or trailer with pigs and CO2 gas should remain sealed for at least 15 to 20 additional minutes prior to transport and disposal. This provides enough time to ensure that all pigs are dead, with no risk of revival when exposed to air. Pigs that may have survived CO2 exposure must be humanely killed using an alternate AVMA-approved method, such as captive bolt or gunshot to the head.

The CO2 system should be used only in well-ventilated areas, and all normal safety precautions for handling high-pressure cylinders and CO2 should be followed. If a used LP tank is to be utilized, it should be thoroughly purged of LP liquid and vapor. Air in the tank must also be purged and replaced with CO2 before the initial euthanasia application. As a safeguard against over-pressurizing any tank used for this application, a pressure relief valve should be included in the system.

Implications

• If designed and operated properly, a CO2 system can be a safe and effective option for on-farm euthanasia of groups of pigs.

• The number of pigs that can be euthanized in one batch is limited only by the size of the chamber and provision of the appropriate flow rate of CO2 for that chamber size.

Acknowledgement

Supported by a USDA APHIS cooperative agreement and a Department of Homeland Security Science and Technology Division Interagency Agreement (System to Administer Inhaled Gases for Mass Depopulation of Swine in a National Emergency).

Conflict of interest

None reported.

References

1. AVMA Guidelines for the Euthanasia of Animals: 2013 Edition. March 2013. Available at: https://www.avma.org/KB/Policies/Documents/ euthanasia.pdf. Accessed 24 June 2014.

2. Meyer RE, Morrow WEM. Carbon dioxide for emergency on-farm euthanasia of swine. J Swine Health Prod. 2005;13:210–217.

3. Whiting TL, Marion CR. Perpetration-induced traumatic stress – A risk for veterinarians involved in the destruction of healthy animals. Can Vet J. 2011;52:794–796.

4. Raj ABM, Gregory NG. Welfare implications of the gas stunning of pigs 1. Determination of aversion to the initial inhalation of carbon dioxide or argon. Anim Welf. 1995;4:273–280.

5. Raj ABM, Gregory NG. Welfare implications of the gas stunning of pigs 2. Stress of induction of anaesthesia. Anim Welf. 1996;5:71–78.

6. Meyer RE, Whitley JT, Morrow WEM, Stikeleather LF, Baird CL, Rice JM, Halbert BV, Styles DK, Whisnant CS. Effect of physical and inhaled euthanasia methods on hormonal measures of stress in pigs. J Swine Heath Prod. 2013;21:261–269.

7. Raj M. Humane killing of nonhuman animals for disease control purposes. J Appl Anim Welf Science. 2008;11:112–124.

8. Transport Quality Assurance Handbook Version 4; 2008:23. Available at: www.pork.org/filelibrary/TQAAdvisor/TQA4Manual.PDF. Accessed 24 June 2014.

9. Stikeleather LF, Morrow WEM, Meyer RE, Baird CL, Halbert BV. Evaluation of CO2 application requirements for on-farm mass depopulation of swine in a disease emergency. Agriculture. 2013;3:599–612. doi:10.3390/agriculture3040599.

10. The Ideal Gas Law. Available at: http://chemwiki.ucdavis.edu/Physical_ Chemistry/Physical_Properties_of_Matter/Phases_of_Matter/Gases/The_Ideal_Gas_Law. Accessed 24 June 2014.